Until 31.03.2023, the Chair of Technical Biology dealt in research and teaching with issues from the three major biotechnological subfields of biological material production, biocatalysis and bioproduct processing. The former OU Technical Biology of the BLT belonged to the Faculty of Chemical Engineering and Process Engineering and started its work in August 2003. In research, about 20 staff members dealt with the development of biotechnology in a future bioeconomy, focusing on biotechnological material production and biocatalysis. In all projects, there was close cooperation with other institutes and departments at KIT, Helmholtz facilities and institutes of the Fraunhofer-Gesellschaft.

Research Overview

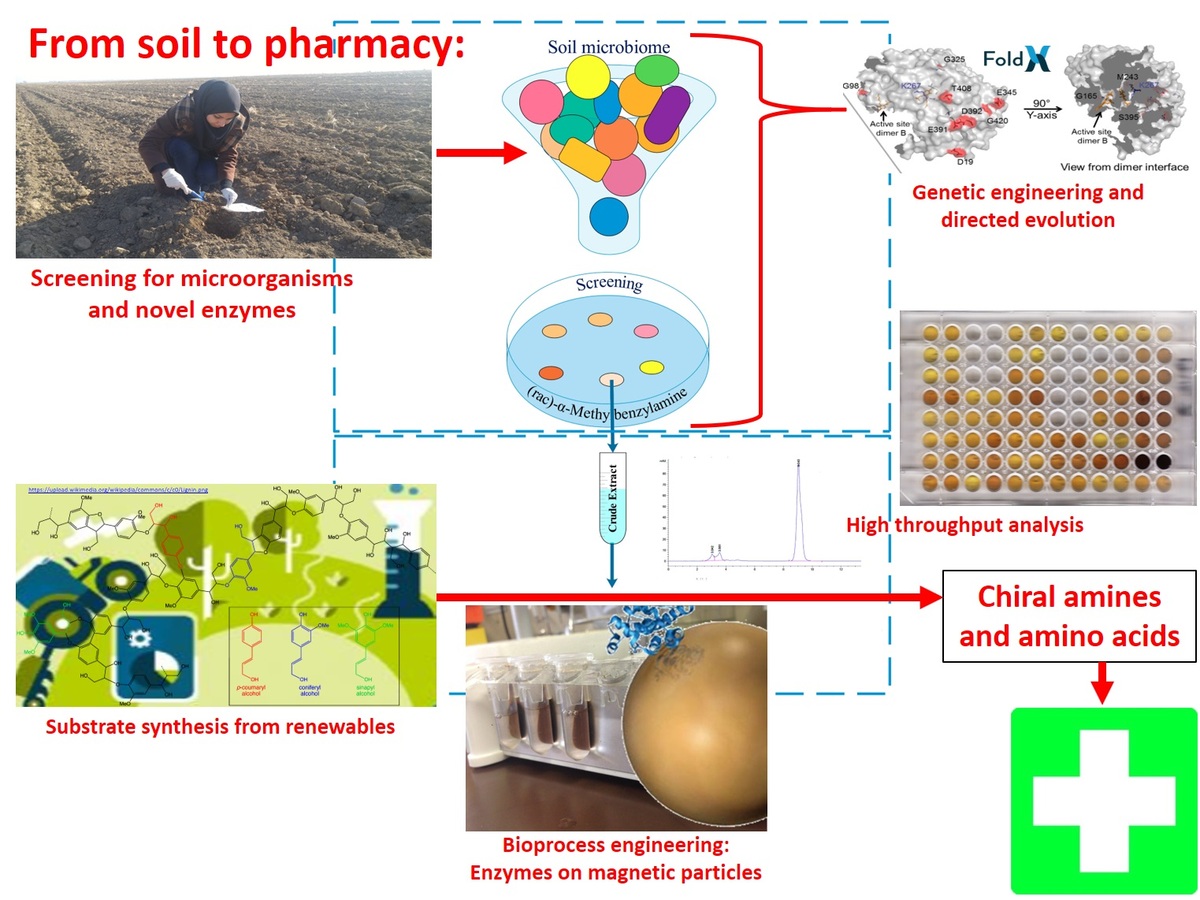

In the context of a sustainable bioeconomy and the associated raw material shift from fossil to renewable raw materials and residues , the aim at BLT-TeBi is to develop biotechnological processes for the biobased production of basic and fine chemicals.

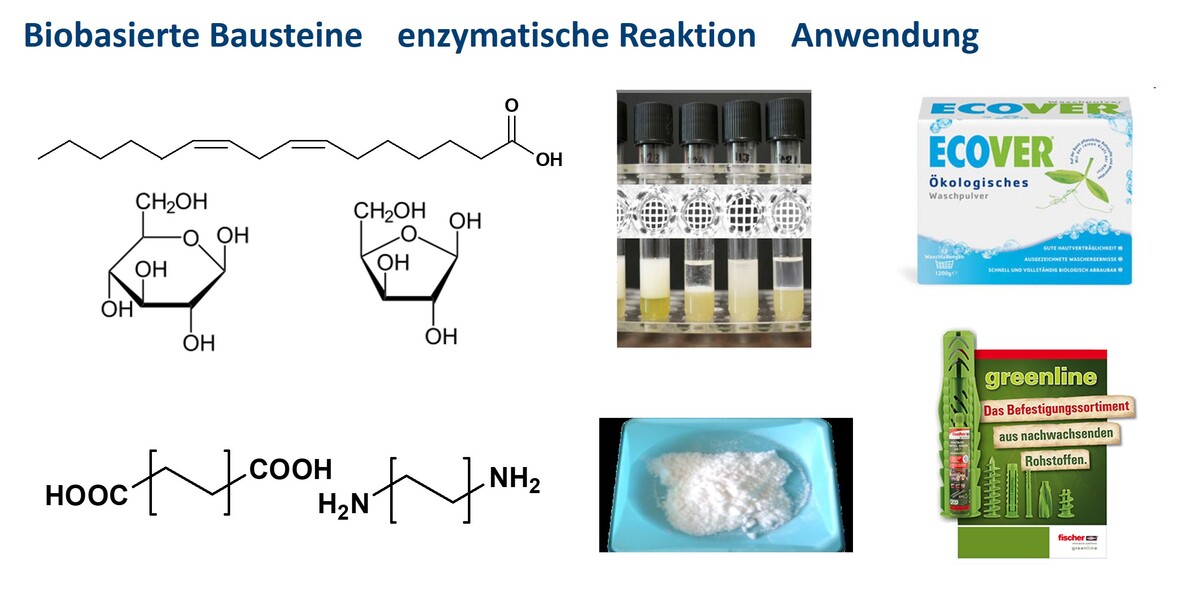

Current research focuses on the microbial utilization of synthesis gas for the production of acetic acid and ethanol as synthesis building blocks. Research continues on the microbial production of organic dicarboxylic acids as plastic building blocks and single cell oils for various applications. Topics of enzymatic mass conversion are the synthesis of glycolipid surfactants as detergents and cosmetics and the recovery of special α- and β-amino acids as precursors for pharmaceuticals.

Characterization of customized biosurfactants -Microbial, enzymatic & chemical synthesis- Prof. Dr. Christoph Syldatk:

Glycolipids are environmentally friendly surfactants with a wide range of applications in cosmetics, detergents and cleaning agents, as well as in food. With the help of enzymes from the natural fat and sugar metabolism of plants and microorganisms, tailor-made biosurfactants with completely new properties can be produced. In order to realize economic applicability, comparative studies with established petroleum-based surfactants are carried out in addition to the development and optimization of enzymatic and microbial processes.

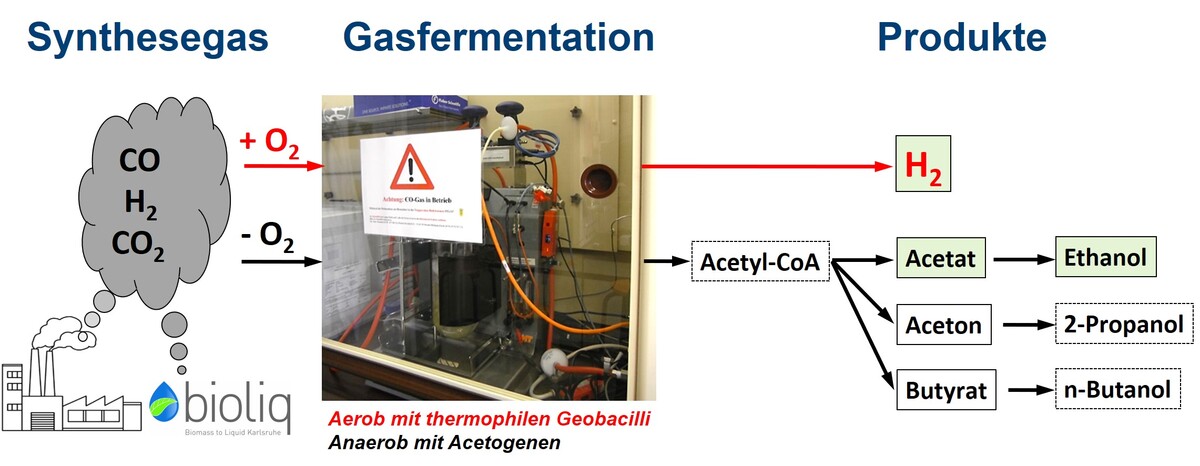

"Fermentation of gaseous substrates" - AkOR Dr. Anke Neumann.

Gaseous substrates are available either as waste stream of the steel industry or as synthesis gas (CO,CO2, H2) from the bioliq® plant at KIT. As the sole source of carbon and energy, they enable the production of organic acids and alcohols by anaerobic gas fermentation. This represents a promising andCO2-neutral alternative to biorefinery concepts previously established on the basis of sugars. The focus of the research is on the selection, characterization and optimization of suitable microorganisms or mixed cultures and the required process control.

Microbial production of dicarboxylic acids and single-cell oils from renewable raw and residual materials - Dr. Ing. Katrin Ochsenreither

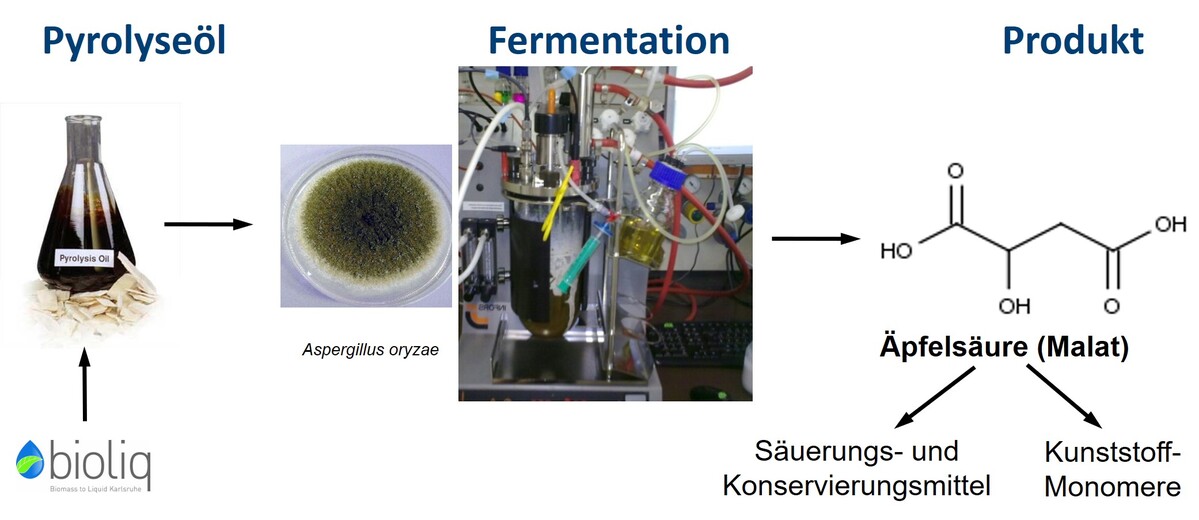

Dicarboxylic acids and single-cell oils produced microbially at low cost from renewable raw materials and residues can be used in a variety of ways as starting compounds for the synthesis of energy sources, surfactants, biolubricants and bioplastics. The object of this work is to investigate the suitability of various lignocellulosic and low-temperature carbonization fractions as substrates, as well as the upstream and downstream processing of the products. Of great interest is the use of the so far hardly investigated group of anaerobic fungi from ruminants.

"Chemoenzymatic reaction cascades to unusual amino acids" - AkR PD Dr. Jens Rudat and DFG junior research group Dr.-Ing. Ulrike Engel.

40% of our drugs and 20% of agrochemicals contain chiral amines and amino acids (AS) as a functional group. A particular challenge for their production is the synthesis of AS whose structure differs from that of proteinogenic AS, e.g. d-AS, β-AS or AS with an unusual side chain.

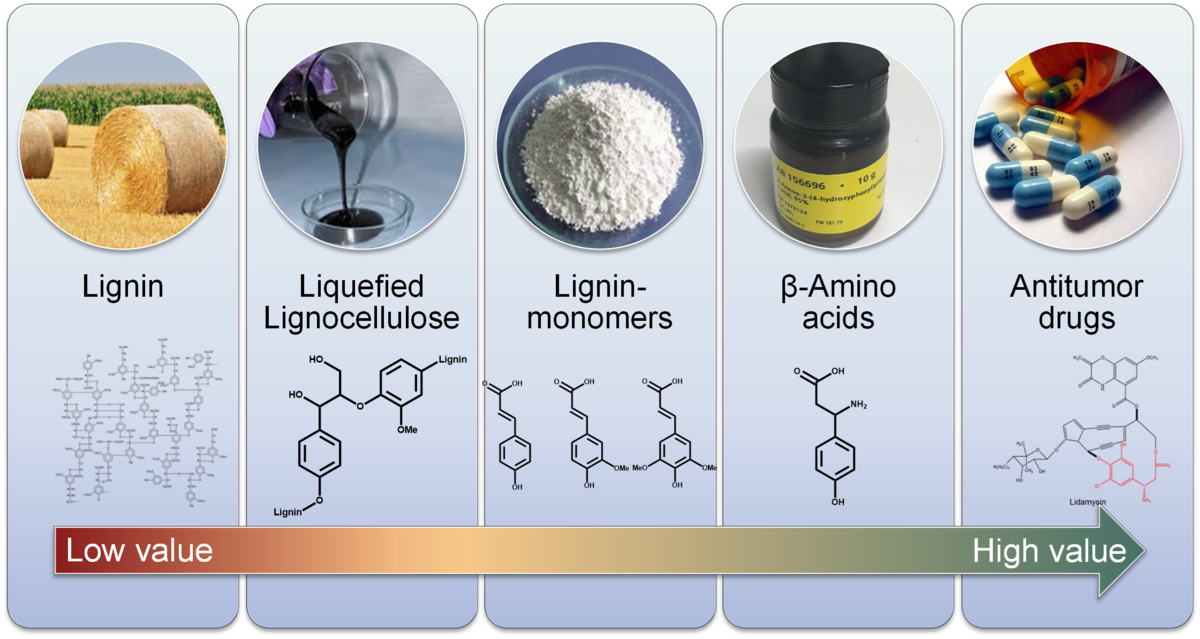

To this end, the Biocatalysis WG is pursuing interdisciplinary approaches from organic chemistry, microbiology, biochemistry, bioinformatics and (bio)process engineering in order to obtain these substances from the lignin fraction of plant waste in the long term with the aid of enzymes.

Metabolic versatility of Parageobacillus thermoglucosidasius for alternative energy resources (MPaeR)

The ability to grow on both organic and gaseous substrates makes the thermophilic, facultatively anaerobic bacterium Parageobacillus thermoglucosidasius a highly interesting chassis for the construction of microbial cell factories. Elucidation of the molecular interactions underlying this metabolic versatility will facilitate the development of rational and selective strategies for use in environmentally friendly bioprocessing. Of particular interest here is the exploration of the regulatory basis of carbon monoxide (CO) oxidation and carbon assimilation.

Enzymatic synthesis of non-canonical amino acids

Non-canonical amino acids are not encoded by the standard genetic code. Prominent examples are the Parkinson's drug l-DOPA, d-phenylglycine derivatives as side chains of ampicillin and amoxicillin (most prescribed antibiotics in children), and β-phenylalanine in the most widely used chemotherapeutic drugs Taxol and Taxotere (against breast and prostate cancer, among others).

Economical access to these molecules and thus to essential drugs is made possible by new microorganisms and enzymes, their bioinformatic modeling and optimization, and by innovative production processes using sustainable substrates.

Further information on our current research topics can be found here:

Biological substance production- Comparative genome analyses of self-screened oleogenic yeasts.

- Lignocellulose: Evaluation of pyrolysis oils as a platform for fermentation

- Synthesis gas fermentation

- Production of lignocellulytic enzymes with chytridiomycetous fungi

- Process waters from thermochemical processes of biomass conversion for microbial matter production

- Establishment of an "oleobiotechnology": production of alkanes and olefins with the help of oleogenic microorganisms

- Evaluation of biotechnological fermentation processes for the production of organic acids on an industrial scale

- Evaluation of pyrolysis oils as a platform for fermentation - Subproject 2: Production of malate with A. oryzae

- Biotechnological utilization of complex side and waste streams using the example of carbonization water and carbonization water fractions

- Development of a biotechnological enzyme cascade process for the production of chiral beta-amino acids

- Molecular Interaction Engineering (MIE), subproject Synthetic Reaction Cascades (SynCasc)

- Lignin-based aromatic amino acids

- Lignocellulose: Enzymatic and microbial synthesis of tailored biosurfactants based on lignocellulose

Completed projects

- Process development for the production of microbial biosurfactants

- Enzymatic production of enantiomerically pure compounds

- Production of non-proteinogenic D- and L-amino acids

- Microbial or enzymatic saponification of sterically hindered nitriles

- Immobilization of enzymes on magnetic particles

- Enzymes from extremophilic microorganisms for technical applications

- Biotechnological cultivation of marine sponges

- Mycotoxins

- Polymeric surfactants: chemozymatic synthesis of acyl peptides

- Application of nitrile hydrolyzing enzymes, linear and cyclic amidases for the production of fine chemicals

- Evaluation of biotechnological fermentation processes for the production of organic acids on an industrial scale

- Evaluation of pyrolysis oils as a platform for fermentation - Subproject 2: Production of malate with A. oryzae

_rdax_1200x573.png)